What are the advantages of a boot washer in the food industry?

Preventing the emergence of microorganisms and preventing cross-contamination, both directly and indirectly, are two of the major challenges that the food industry faces every day.

The application of strict food handling protocols, as well as the development of progressive technological solutions, are the reason why safety is nowadays the norm in the industry. The use of boot washers in the food industry, in particular, responds precisely to this development because it provides a highly efficient solution.

Establishing a hygienic protocol

The adoption of a manual of Good Hygienic and Handling Practices, as well as its implementation in day-to-day operations by operators, is a determining factor in terms of safety in the industry. The guarantee of safety for the final consumer of the product is produced when it is handled by professionals who apply knowledge received with constant, updated and precise training.

All hygiene protocols agree that footwear has a key importance. Boots used for professional work, in particular, can only be sanitized in a different room, and specifically in a space where there is, if possible, a boot-washing machine. This ensures that contaminants do not 'travel' from one room to another via the soles of the boots. Boot washers allow all employees to thoroughly disinfect their footwear, eliminating the potential for contamination by footwear-borne bacteria.

Ensure proper disinfection of footwear on operators

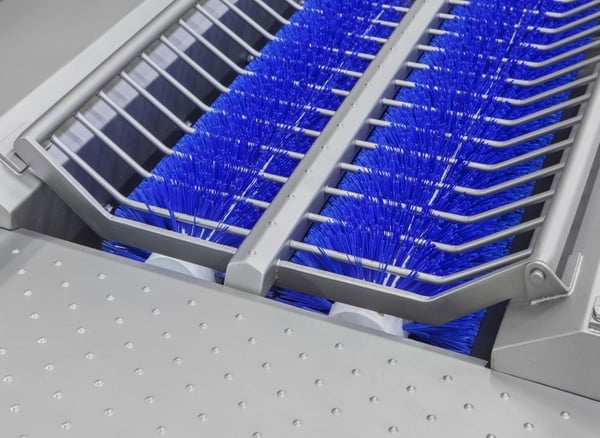

The soles and uppers of boots used in the food industry are the most likely to transmit contaminants if they are not sanitized, something that can be achieved with boot washers in the food industry, which are designed to clean these elements in an ergonomic manner. Industrial hygiene station, on the other hand, are manufactured and designed to facilitate the transit of numerous staff and can withstand intensive daily use.

In addition to having a fixed sole scrub brush and a manual scrub brush, which emits a jet of water, these devices are intuitive and simple to use, which facilitates compliance with usage protocols. It is common for many models on the market to combine a disinfection bath with the application of a disinfectant in the sole area.

How to choose a boot washer for food industry?

In order to establish the best hygienic protocol, multiple solutions can be used, depending on the specific needs and the available budget, but in every case is advisable to use an automatic boot washer, which facilitates an agile and constant flow of several operators. A good example of quality and service guarantee is the integrated hygiene station Sanieco WD Plus, which has 3 brushes, a continuous boot and sole washing system that also offers handwashing and drying in the same area and without contact.

This equipment, which allows the flow of one person every 18 seconds, guarantees a drastic reduction in the risk of cross-contamination. Together with careful separation of food processing areas and operator training, it is the best way to prevent cross-contamination and additional safety risks.

Food industry certifications ensure that a number of standards are met, both in terms of quality and safety, which are crucial for the food industry. The boot washers for the food industry are very helpful tools when it comes to meeting the requirements proposed by certificates such as FSSC 22000, BRC Global Standard for Food Safety or the IFS Protocol, among others.