The challenges of food safety in the industrial sector

Food safety must be regulated by the highest standards in an industry that must always offer maximum guarantees. At stake is the health of consumers, who trust the processes and protocols implemented by those involved in the food chain. Below we review the main points to consider in terms of food safety in the industrial sector.

Cleanliness as the main point

What are the main points in the fight for food safety in the industrial sector? Ensuring proper hand disinfection of operators, avoiding the presence of pathogens in food and eliminating the possibility of contamination. Cleanliness plays a key role because everything depends on it; without cleanliness, the sanitation requirements of the products cannot be guaranteed.

Industry certifications such as FSSC 22000, BRC Food, or the IFS Protocol (International Food Standard), among others, to which ISO 22000 can be added, focus on ensuring cleanliness before, during and after food handling.

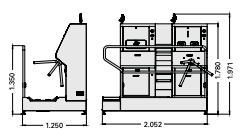

Hygienic and efficient design

Hygienic and efficient design of equipment and work tools in the industry is understood to mean everything aimed at guaranteeing compliance with strict cleaning and safety protocols. It is not enough for hygiene stations and other elements to fulfill their function, but they must do so efficiently, without the possibility of error. Food safety in the industrial sector rests, to a large extent, on the very conception with which all the means used in the handling of food have been manufactured.

Risk prevention

Preventing risks rather than repairing the damage they cause is not only more efficient, but also more economical. In order to ensure food safety in the industrial sector, it is essential that operators know and apply a protocol for daily actions.

Protocols should be established indicating how to act before entering the changing room that serves as a prelude to the cutting and food handling areas. Operators should also be provided with clothing included in the HACCP programme, as well as equipment and materials that protect against microorganisms, such as those made of stainless steel.

Food safety control

Food safety faces challenges in terms of control, starting with prevention. It faces developments that are supported by growing R&D, which achieves advanced preservation techniques. Within this section, technologies are being developed that enhance the traceability of food within the agri-food chain or ‘smart’ packaging, which itself becomes an antimicrobial agent.

Food safety control is undergoing constant improvements that also point to more sustainable and environmentally friendly solutions, such as improved waste control or the use of biodegradable products.

Appropriate analysis

Technology is a great ally in food safety in the industrial sector. The development of applied innovation projects has resulted in cleaning and sanitizing equipment. These are able to analyze the movements of an operator or to detect whether hands have not been washed due to the supply of soap. A good example of this is the Hygiene Control System (HCS) technology, the first integral in-line control system for hygiene equipment capable of providing the most advanced solutions in terms of safety.