The importance of hand hygiene

Hand hygiene in the food industry is a determining factor in preventing both microorganisms from appearing in food and cross-contamination between different areas. Cross-contamination, especially indirect cross-contamination, is caused to a large extent by carelessness in the hygiene of operators due to a false sense of safety and hygiene once inside the plant. The hands of food handlers must be washed and disinfected regularly to ensure safe food handling.

The key to maintaining good hygiene

In order to maintain proper hand hygiene in the food industry, it is necessary to focus on both the personnel and the tools and equipment used during the manufacturing processes With an adequate cleaning policy, it is possible to reduce the risk of the appearance and spread of pathogens such as Salmonella or E. coli, among others.

It is essential to plan an action protocol in which the steps that must be followed to handle the products in an optimal way in each of the phases are set out. In addition, staff must be made aware of the importance of implementing these actions, as well as an action plan to ensure compliance.

How to ensure proper hand disinfection of operators

Operators should clean and disinfect their hands according to the following steps:

- Wetting. Hands should be thoroughly wetted with potable water or water fit for human consumption.

- Soaping up. Next, soap or hand wash is applied proportionately and evenly over the entire surface, from the heel of the hand to the fingertips, including the entire palm and the entire back of the hand.

- Rubbing. Hands should be rubbed together, with special emphasis on the space between the fingers and under the nails.

- Rinse. Rinse hands with abundant water until all soap is completely removed.

- Remove the water. Dry hands completely with paper towels or an air curtain. Effective drying is as important as thorough hand washing, as micro-organisms are more likely to reproduce on damp surfaces.

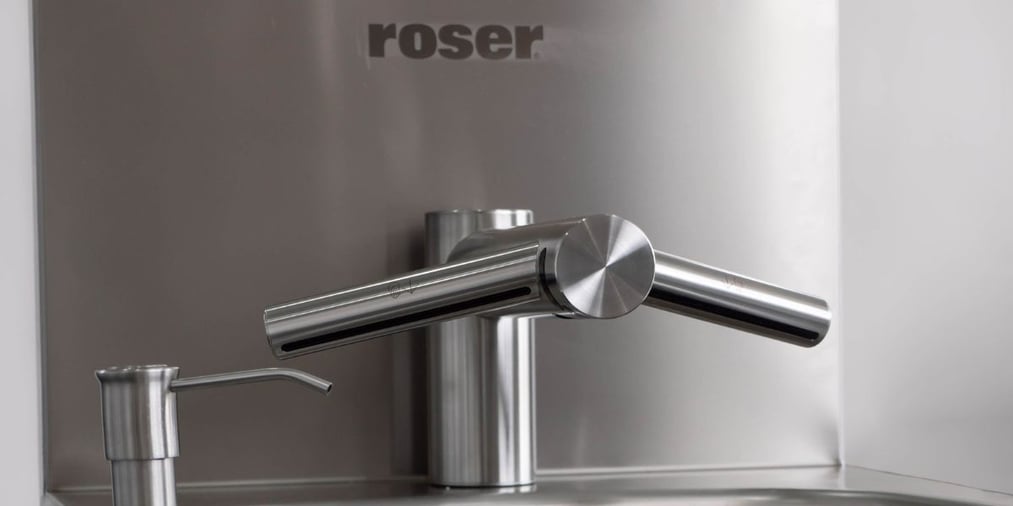

- Disinfection. Once the hands have been cleaned, with the consequent removal of dirt and grease, it is time to disinfect them with a hydroalcoholic antiseptic in the form of a gel or solution. Its diffusion must come from non-contact devices, such as all our equipment.

Preventing pathogens in food

In order to promote hand hygiene in the food industry, we must bear in mind that proper hand washing is essential and the best way to prevent pathogens from proliferating in food. Hand hygiene should take place before starting to handle food and before using gloves. Also after handling equipment of various types or coming into contact with raw products of animal origin.

Operators should be aware that the process is also mandatory if they have been to the toilet or ingested any food or drink. Also after actions such as smoking, coughing, sneezing, scratching or touching the face. If a handkerchief is needed, it should be disposable. The same process should be applied after handling rubbish or waste and after each work break.

Minimize incidences of food contamination

Preventing the transfer to food of pathogens such as viruses and bacteria on the hands of food handlers is synonymous with safety. But it doesn’t stop there; regular cleaning and disinfection of materials and tools used to handle food is key. These must be cleaned after each use and have their own sanitation plan. They should not leave the facilities.

With the correct disinfection of surfaces, chambers and facilities where all these operations are carried out, a complete plan of action is completed to ensure food safety throughout the handling process.