How to avoid contamination in a food room?

Avoiding contamination in a cutting room is essential to ensure the safety of the foodstuffs being processed. Both the proliferation of certain micro-organisms and cross-infection are risks that must be avoided. To do so, there are a number of good practices that must be applied. Hand hygiene is one of the main ones, but not the only one.

Hygiene starts in the locker room

The first point of contact between operators and the facilities in which they are to perform their duties is not, as one might think, the cutting or processing plant itself. Beforehand, they must pass through a changing room where they are uniformed with their work PPE, including boots. This room is accessed with street clothes and footwear. It is therefore essential to keep this area clean and to ensure that no organic matter enters it.

This objective should be set both when entering the changing room before the start of the working day and when leaving it after work. Otherwise, a dangerous breeding ground for pathogens such as bacteria, viruses and fungi will be created. Cleaning before and after entering the cutting room also extends to any exit of employees, for instance during rest periods.

Use good material (stainless)

Ensuring food safety also requires the use of material that protects the locker rooms from microorganisms. Stainless steel lockers offer the best antibacterial performance, since it is a non-porous material and, at the same time, it is highly resistant to humidity, which prevents the spread of pathogenic agents.

Stainless steel is resistant to degradation and can withstand very low or very high temperatures and, if they occur, sudden changes from one to the other. This material, therefore, stands out for its long service life and its resistance to impacts.

Look for products designed to prevent contamination

Preventing contamination in the cutting room should be a priority objective for any company involved in food processing. On the one hand, operators must be made aware of the best practices to be developed and the importance of their daily performance. On the other hand, it is necessary to apply a daily protocol that defines how to handle each product in an optimal way.

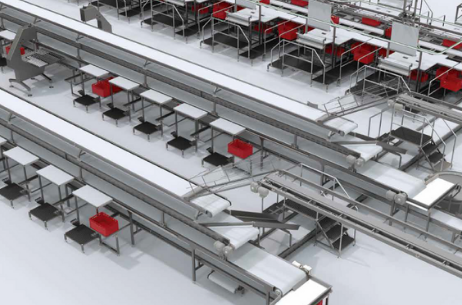

However, all of this would not produce the desired results without equipment and products that meet the requirements ofcleaning, disinfection and sanitisation. This includes everything from the use of stainless steel equipment, to practices such as avoiding flat horizontal surfaces, so that dirt does not accumulate on them. Regarding operators’ clothing, should be submitted a number of specific characteristics for the food sector. These are included in the HACCP (Hazard Analysis and Critical Control Points) programme. Among these particularities are the use of durable materials, no buttons or pockets above the waist, or color coding of garments to differentiate between employees in different areas.

Avoid contamination of the cutting room at both the infeed and outfeed

In the food processing industry, avoiding contamination in the cutting room is critical. That’s why it must be permanently clean, so as to prevent cross-contamination and the appearance of dangerous microorganisms. But this sanitisation begins before, at the entrance and exit and, therefore, in the changing rooms, where the operators enter from the street and where they deposit their personal clothing and footwear. The fact that utensils and clothes leave the room clean to avoid pathogens and the generation of bacterial cultures is, in practice, an effective barrier to prevent potentially dangerous situations.