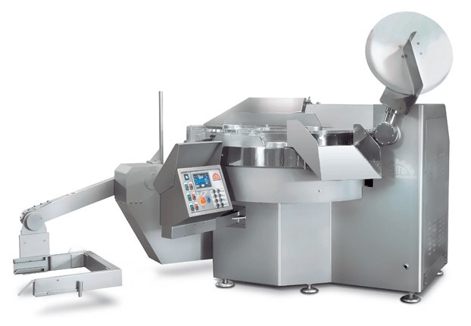

Bowl cutter for emulsions in the meat industry

In the meat industry, the production of emulsions and processed products requires specialised machinery to achieve optimum results. Among the key machines is the bowl cutter, a versatile and efficient piece of equipment that plays a key role in producing quality products.

Benefits of using an emulsion bowl cutter in meat production

The bowl cutter has become an indispensable tool in the meat industry due to the numerous benefits it offers. Here are some of the key aspects:

- Efficient production: The industrial cutter enables fast and homogeneous mixing of ingredients, achieving consistent, high-quality emulsions in a reduced time. This speeds up the production process and increases plant productivity.

- Improved texture and taste: Thanks to its powerful cutting and mixing capabilities, the bowl cutter ensures a homogeneous emulsion, which translates into a better texture and taste of the final products. It also facilitates the incorporation of seasonings and additives, ensuring even distribution throughout the mixture.

- Control over the process: The bowl cutter allows parameters such as cutting speed and mixing time to be adjusted, giving greater control over the emulsification process. This is essential to adapt to the specific needs of each product and ensure consistent results.

Tips for maintenance and care of an industrial emulsion cutter in the meat industry

To ensure optimal performance and a long service life of this equipment, it is important to follow some maintenance and care guidelines. Here are some key tips:

- Regular cleaning: It is essential to clean the bowl cutter regularly to remove food residues. Use suitable cleaning products and be sure to rinse and dry all parts properly.

- Preventive maintenance: Perform periodic checks to verify the condition of blades, seals and other components of the equipment.

- Training and proper use: Train the personnel in charge of handling the industrial cutter to follow the safety instructions and use the equipment correctly. This will ensure efficient use and minimise the risk of accidents.

Types of bowl cutter for emulsions available on the market

At ROSER, we offer a range of equipment of exceptional quality and performance. Some of the featured models include:

- The cato line of cutters - CT 200 / CT 300 / CT 500: The unique and robust design ensures total freedom from vibration throughout the entire service life. Fast emulsification of thin pastes with minimal heat-up and a variety of equipment options. These models provide optimum performance for high production rates.

- The Cato Cutter line - CT 75 / CT 120 / CT 150: Fast emulsifying of thin pastes with minimal heating and a variety of equipment options. Ideal for medium production runs.

The bowl cutter for emulsions has become an indispensable ally for the meat industry, enabling quality products to be obtained efficiently and homogeneously. With the benefits it offers in terms of efficiency, texture and process control, its proper maintenance and the variety of models available on the market, it is a valuable investment for any meat production plant. Discover the industrial cutter solutions offered by ROSER and take the quality of your products to the next level.